Ideas become reality

Free expression

becomes reality

EMARF is a design to production platform enabling a seamless connection from design to manufacturing.

EMARF is a design to production platform enabling a seamless connection from design to manufacturing.

Daiwa Akihabara Building - Entrance Bench

Design: Taisei Corporation

Tachiyama Ikoi no Mori - Festival Square Public Toilet

Design: Yamashita Design

NTT DATA INFORIUM TOYOSU INNOVATION CENTER

Design: KOKUYO photo: Tomooki Kengaku

Nikken Sekkei Tokyo Office Collective Floor PYNT

Design: Nikken Sekkei

Ecological Co WorkScape

Design: SUGAWARADAISUKE Architecture Office

Daiwa Akihabara Building Entrance Bench

Design: Taisei Corporation

Tachita Mountain Recreation Forest - Festival Square Public Toilet

Design: Yamashita Design

NTT DATA INFORIUM TOYOSU INNOVATION CENTER

Design: KOKUYO photo: Tomooki Kengaku

Nikken Sekkei Tokyo Office Collective Floor PYNT

Design: Nikken Sekkei

Ecological Co WorkScape

Design: SUGAWARA DAISUKE Architectural Office

For individuals

For individuals

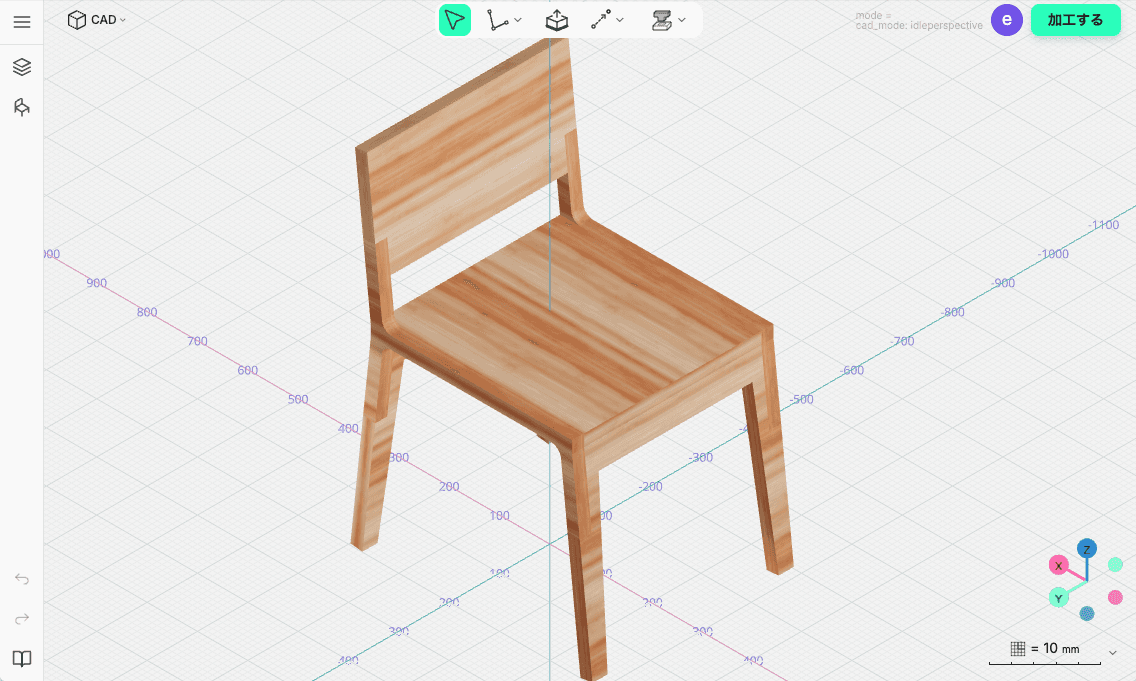

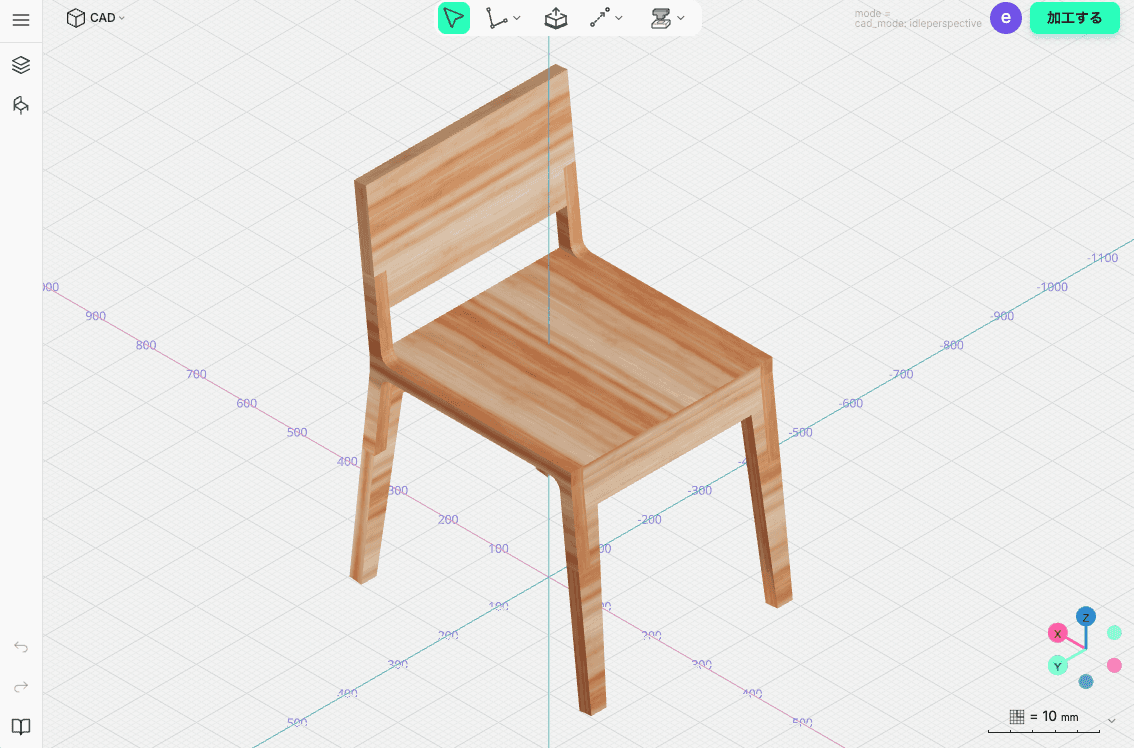

EMARF CAD/CAM

EMARF CAD/CAM

Upload data to complete the processing of furniture and architectural components online!

Upload data to complete the processing of furniture and architectural components online!

D

r

a

w

Y

o

u

r

s

e

l

f

Draw it yourself

Make it yourself

D

e

s

i

g

n

t

o

B

u

i

l

d

Request

for

Production

NEW

Request production

NEW

For businesses

For businesses

EMARF design and construction services

EMARF Production and Construction

Service

Just submit a render or drawing,

and we can support you through the whole process, from detailed design and data creation, to production and installment!

Just submit a render or drawing,and we can support you through the whole process, from detailed design and data creation, to production and installment!

Order

NEW

Or

plywood, CLT

plywood, CLT

2D machining

2D machining

Data

Data

Materials

Materials

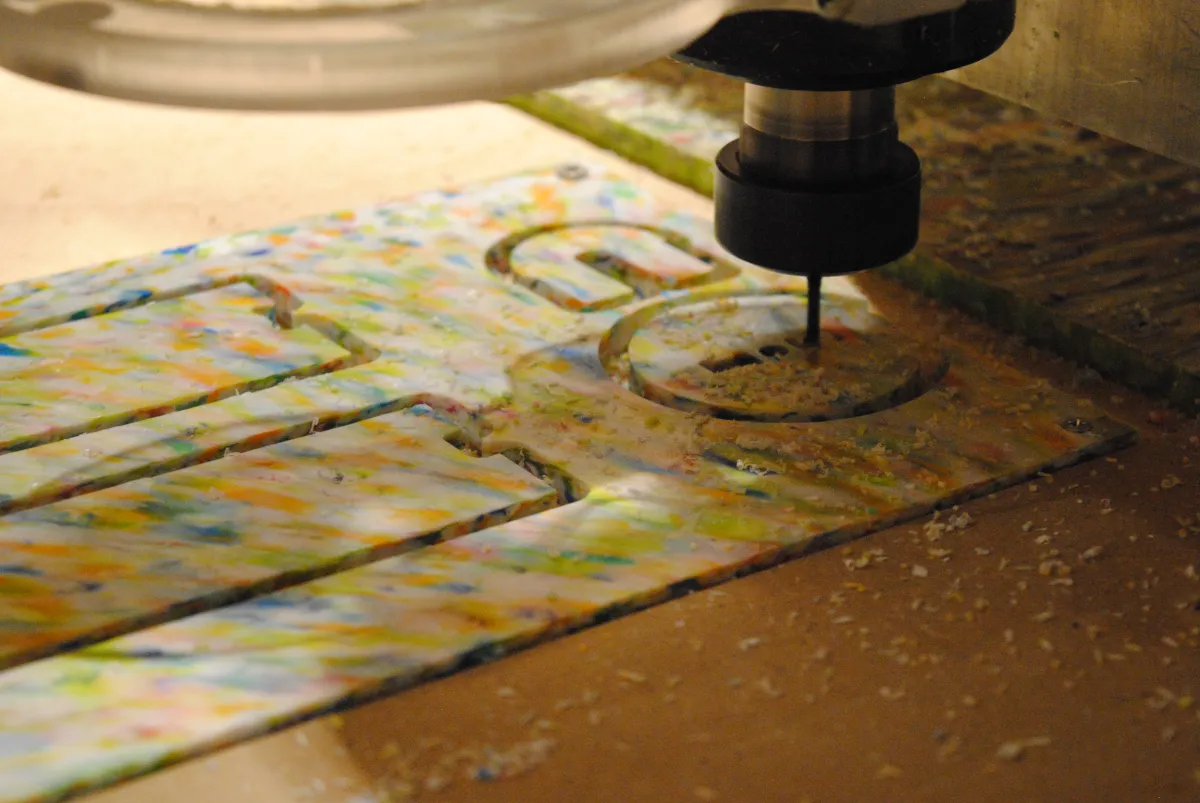

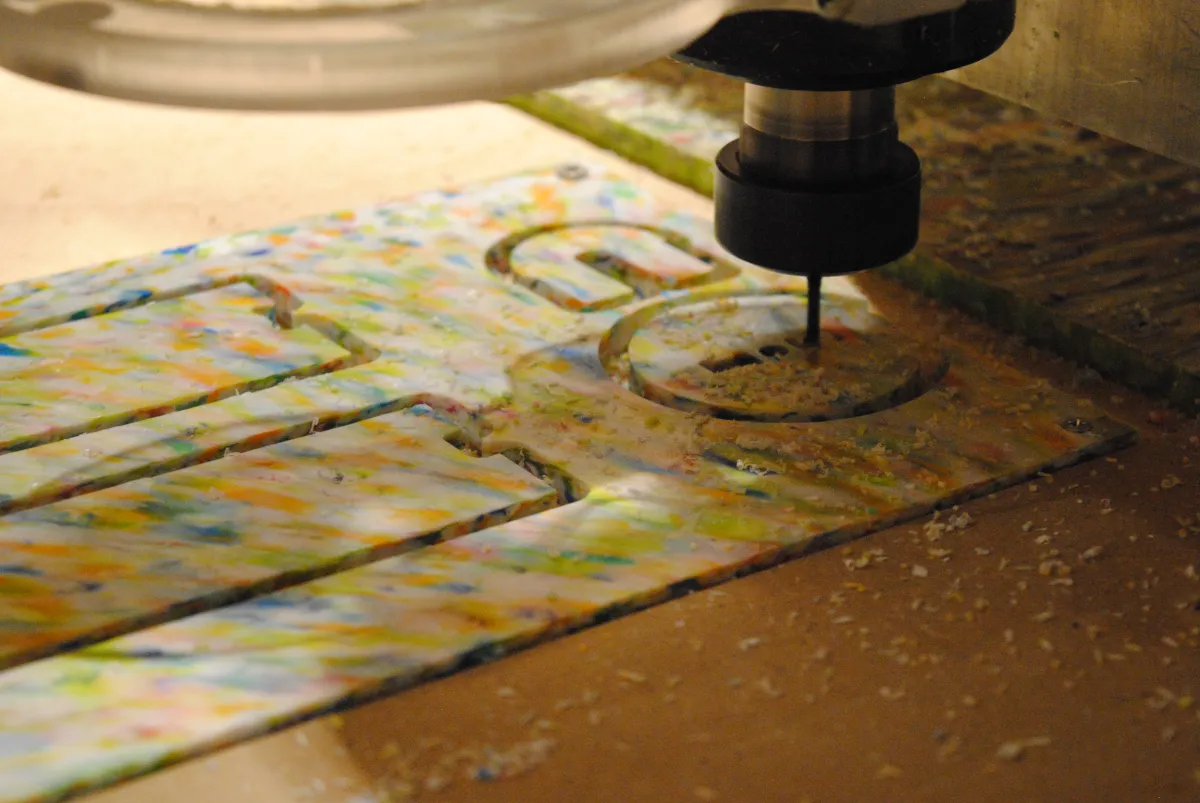

Processing

Processing

render, sketch, technical drawing

render, sketch, technical drawing

plywood, CLT, etc.

special materials

plywood, CLT, etc.

special materials

2D machining, double-sided machining,

2.5D machining, 5-axis CNC machining

2D processing

Double-sided processing

2.5D processing

5-axis CNC processing

2D Processing Double-Sided Processing

2.5D Processing 5-Axis CNC Processing

For businesses

At EMARF, we offer cost-effective and high-quality design and construction leveraging digital fabrication, as well as specialized material processing, application development, and more. We are committed to providing the best solutions tailored to your needs. Please feel free to reach out to us for a consultation.

Optimizing workflow

Sixth industrialization of forestry

Digital transformation in design

Special processing

Design using AI

Consulting

つくりながら考える|読みもの

Download a handbook

A detailed look at EMARF case studies,

specialised manufacturing using EMARF,

examples of applications utilising the EMARF system etc.

Work flow

Do it yourself

01

Prepare and submit design data

Prepare the design data in Rhinoceros, Fusion or other design tools that can export DXF files. Upload the data via plugin or directly upload the DXF file to EMARF.

02

Set materials and options

Select options such as materials, chamfering, and finishing. The layout of components within the material is also determined at this stage.

03

Confirm the estimated cost and place the order.

Check the estimated cost and proceed with the order.

04

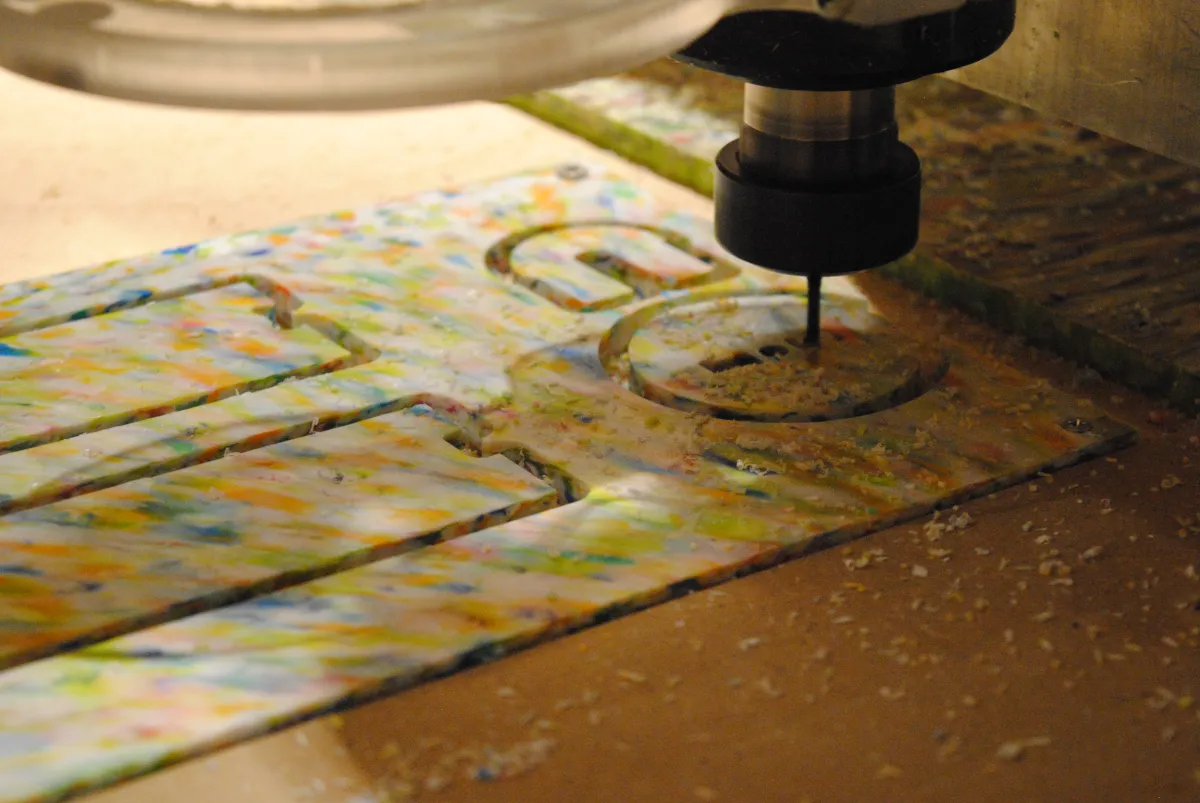

Processing of parts

The order will be sent to manufacturers nationwide. The parts will be cut, packaged and sent to the customer’s address. It is also possible to choose direct pickup from the processing site.

05

Assemble the received parts

Assemble the parts and complete your project.

01

Prepare and submit design data

Prepare the design data in Rhinoceros, Fusion or other design tools that can export DXF files. Upload the data via plugin or directly upload the DXF file to EMARF.

02

Set materials and options

Select options such as materials, chamfering, and finishing. The layout of components within the material is also determined at this stage.

03

Confirm the estimated cost and place the order.

Check the estimated cost and proceed with the order.

04

Processing of parts

The order will be sent to manufacturers nationwide. The parts will be cut, packaged and sent to the customer’s address. It is also possible to choose direct pickup from the processing site.

05

Assemble the received parts

Assemble the parts and complete your project.

01

Prepare and submit design data

Prepare the design data in Rhinoceros, Fusion or other design tools that can export DXF files. Upload the data via plugin or directly upload the DXF file to EMARF.

02

Set materials and options

Select options such as materials, chamfering, and finishing. The layout of components within the material is also determined at this stage.

03

Confirm the estimated cost and place the order.

Check the estimated cost and proceed with the order.

04

Processing of parts

The order will be sent to manufacturers nationwide. The parts will be cut, packaged and sent to the customer’s address. It is also possible to choose direct pickup from the processing site.

05

Assemble the received parts

Assemble the parts and complete your project.

Unlocking DESIGN for everyone

Unlocking DESIGN for everyone

We are developing a web-based design tool,

allowing anyone to design using EMARF,

regardless of their tools or environment.

We are developing a web-based design tool,

allowing anyone to design using EMARF,

regardless of their tools or environment.

feature

.01

Creation and arrangement of shapes

Design elements can be created and arranged entirely in the web interface.

feature

.01

Creation and arrangement of shapes

Design elements can be created and arranged entirely in the web interface.

feature

.01

Creation and arrangement of shapes

Design elements can be created and arranged entirely in the web interface.

feature

.02

Import external files

Import DXF files made with 2D CAD software such as Illustrator and AutoCAD.

feature

.02

Import external files

Import DXF files made with 2D CAD software such as Illustrator and AutoCAD.

feature

.02

Import external files

Import DXF files made with 2D CAD software such as Illustrator and AutoCAD.

feature

.03

Automatic generation of joints

Joints which are typically time-consuming to design such as rabbets, mortises and tenons can be generated with the click of a button.

feature

.03

Automatic generation of joints

Joints which are typically time-consuming to design such as rabbets, mortises and tenons can be generated with the click of a button.

feature

.03

Automatic generation of joints

Joints which are typically time-consuming to design such as rabbets, mortises and tenons can be generated with the click of a button.

EMARF functionality continues to evolve

EMARF functionality continues to evolve

3D machining

COMING SOON

Multi-axis machining

COMING SOON

Edge rounding

COMING SOON

Playback Plan

Acrylic

Aluminum

Playback Plan

Acrylic

Aluminum

Playback Plan

Acrylic

Aluminum

Recycled plastic

COMING SOON

Structural analysis tools

COMING SOON

Easy assembly

COMING SOON

Export drawings

COMING SOON

database

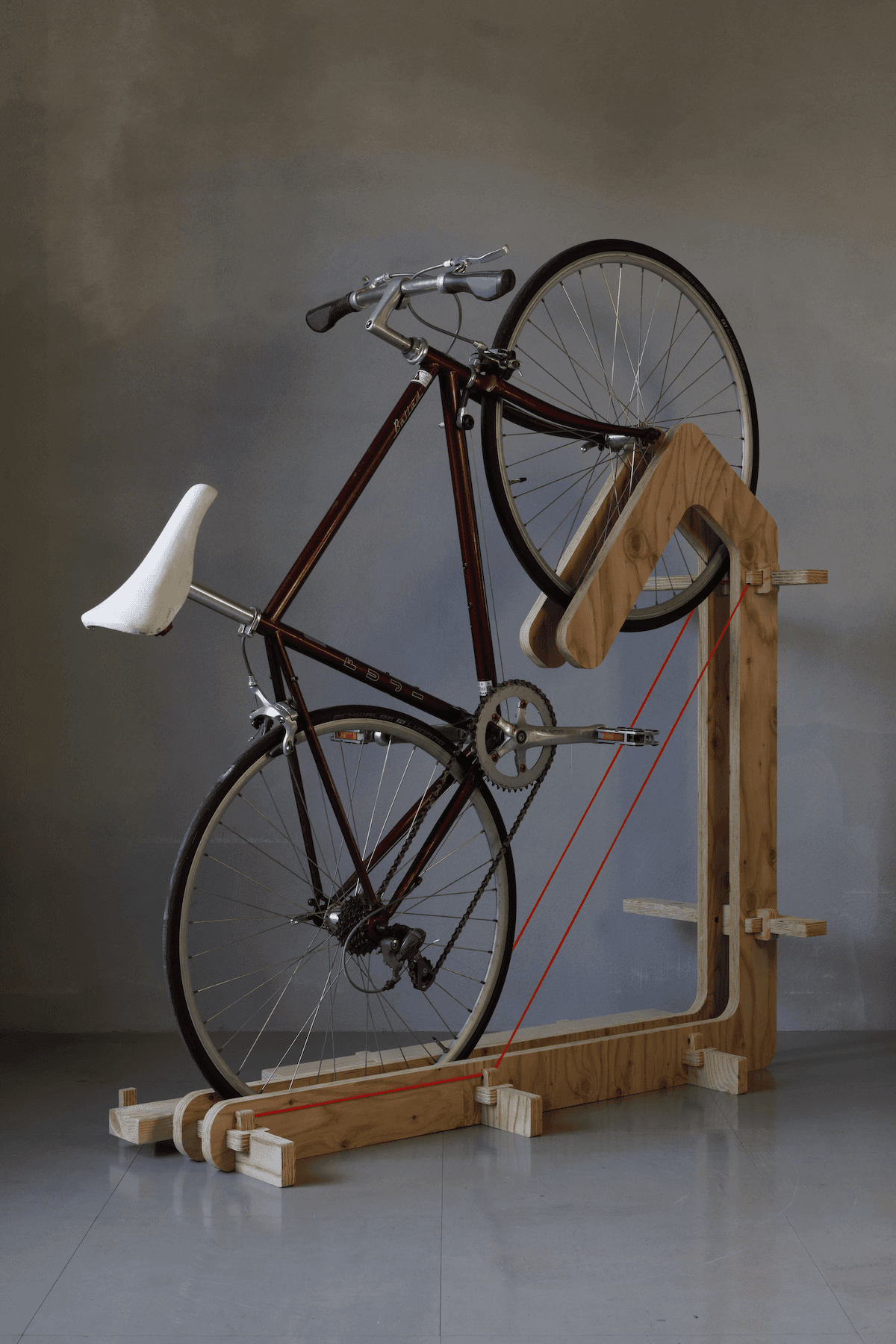

Get inspired by case studies

Get inspired by case studies

If the data is publically shared by the designer, you can refer to the details of their design, materials, processing conditions etc, to inspire your own work.

If the data is publically shared by the designer, you can refer to the details of their design, materials, processing conditions etc, to inspire your own work.

Frequently asked questions

© 2024 VUILD, Inc.

© 2024 VUILD, Inc.

© 2024 VUILD, Inc.

© 2024 VUILD, Inc.

© 2024 VUILD, Inc.

© 2024 VUILD, Inc.